loyalty and artistry: The Lazada x suarez & sons Collaboration

The art of craftsmanship is alive and well in our local community, and nothing exemplifies this more than the beautiful Lazada Ring & Pendant Awards. These stunning pieces of jewelry are a testament to the talented hands of our local artisans, who have worked tirelessly to create something truly unique and special.

The process of creating the Lazada Ring & Pendant Awards is a true labor of love. It involves a highly precise and meticulous process that ensures the final product is of the highest quality.

Wax Injection

The wax injection is a commonly used process in the manufacturing of jewelry and other metal products. In this process, a mold is created to replicate the desired design of the final product. The mold is then filled with wax and allowed to cool and solidify. Once the wax has hardened, it is removed from the mold, creating a wax model of the product.

Once the wax model is approved, it is used to create a mold for the final product using a process called lost-wax casting.

lost-wax casting process

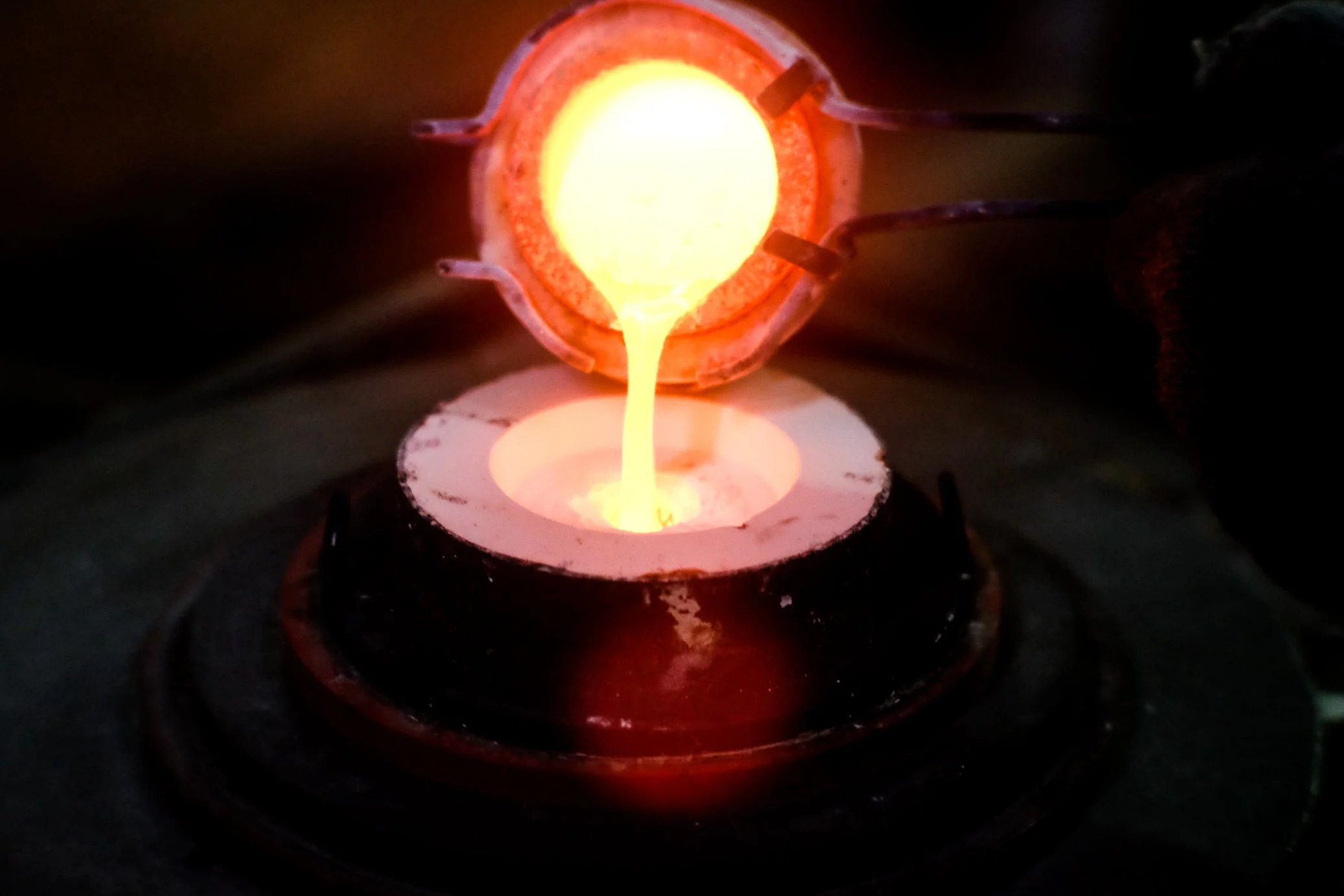

The wax model is encased in a plaster-like material and then heated to melt the wax and create a cavity in the plaster. The silver or gold material is then melted in a crucible, which is a heat-resistant cylinder designed to hold the liquid metal. The metal is heated to a temperature of around 800°C to 1000°C, or until it reaches a fully molten state. The metal is also usually alloyed with other metals to increase its strength and durability.

The metal is poured slowly and steadily to avoid any air bubbles forming in the mold, which could cause defects in the final piece.

CLEANING

The casted material is then soaked in water. This helps to loosen and dissolve any remaining investment powder or other debris that may be attached to the surface of the metal. It should be dried thoroughly using a soft cloth or air dryer. Any excess moisture can lead to corrosion or other damage to the metal surface.

The cleaning process after casting is a critical step in creating high-quality jewelry. By using the proper techniques and materials, jewelry makers can ensure that their casted pieces are free of impurities and ready for further processing and finishing work.

POLISHING

The final step is polishing which helps to enhance the shine, luster, and overall appearance of the piece. Different polishing tools may be used depending on the type of jewelry and the level of polishing required. Some common polishing tools include polishing cloths, buffing wheels, and polishing compounds.

The jewelry is held against the polishing tool with gentle pressure and moved in a back-and-forth or circular motion to achieve an even and consistent finish.

The Lazada Pendant in silver material to be awarded for their 3-Year employees.

The Lazada Ring in 14K gold material to be awarded for their 5-Year employees.

These pieces are truly works of art that showcase the incredible talent and skill of our local artisans. Our skilled craftsmen and women have dedicated their lives to perfecting their craft and creating beautiful pieces of jewelry that capture the imagination and inspire the soul.

The loyalty of Lazada's employees is a key factor in the success of the company. The artistry of our local artisans here in Suarez & Sons Inc. is demonstrated through these pieces of jewelry. Both of these hardworking individuals have shown their dedication to both companies and their customers through their commitment to providing excellent service and delivering high-quality products.

By celebrating both the loyalty of Lazada's employees and the artistry of Suarez & Sons Inc.'s local artisans, the Lazada Ring & Pendant Awards serves as symbols of the power of collaboration and the importance of supporting each other in our work and our lives. It is a beautiful example of what can be achieved when we work together to create something truly special.